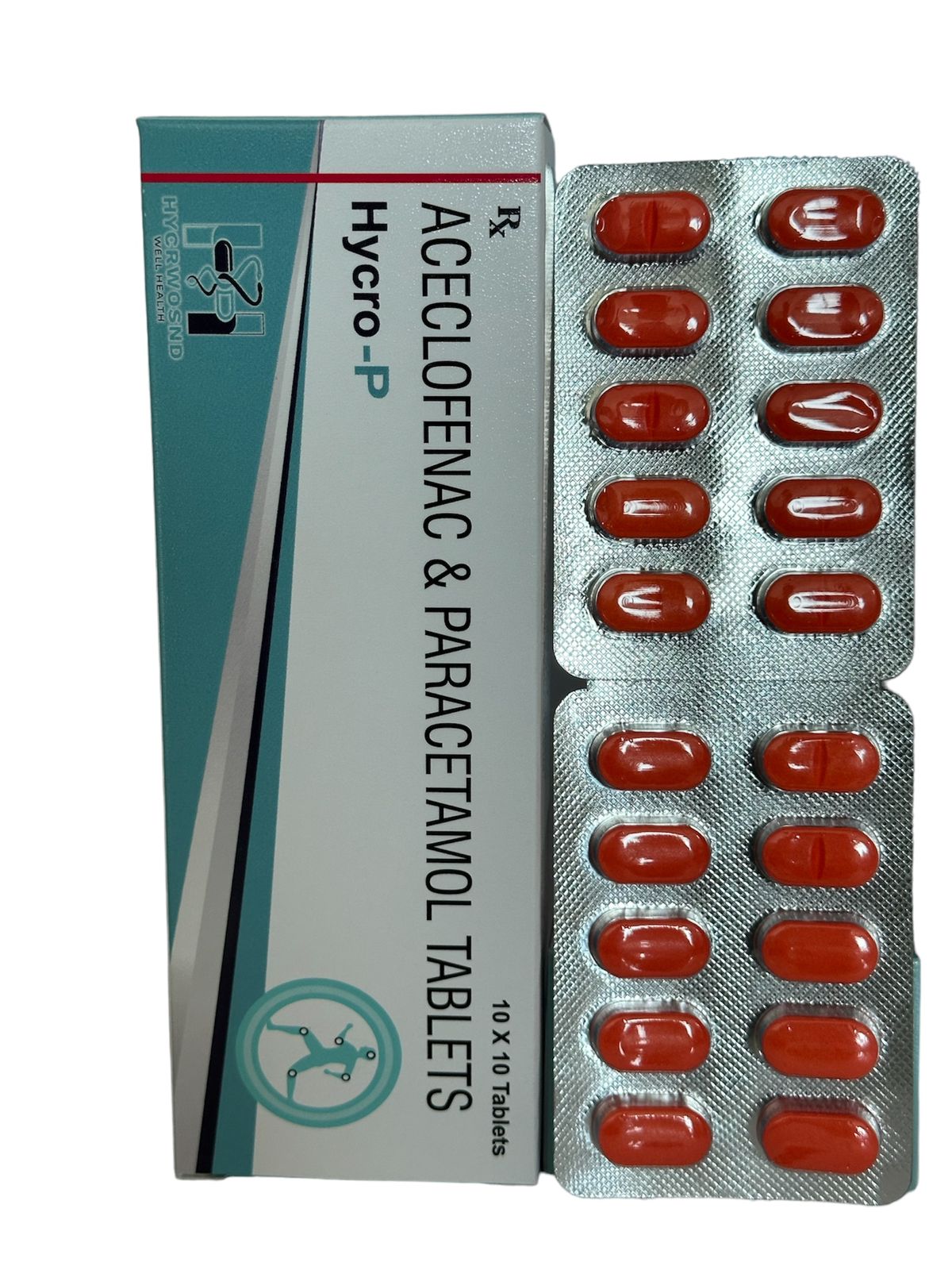

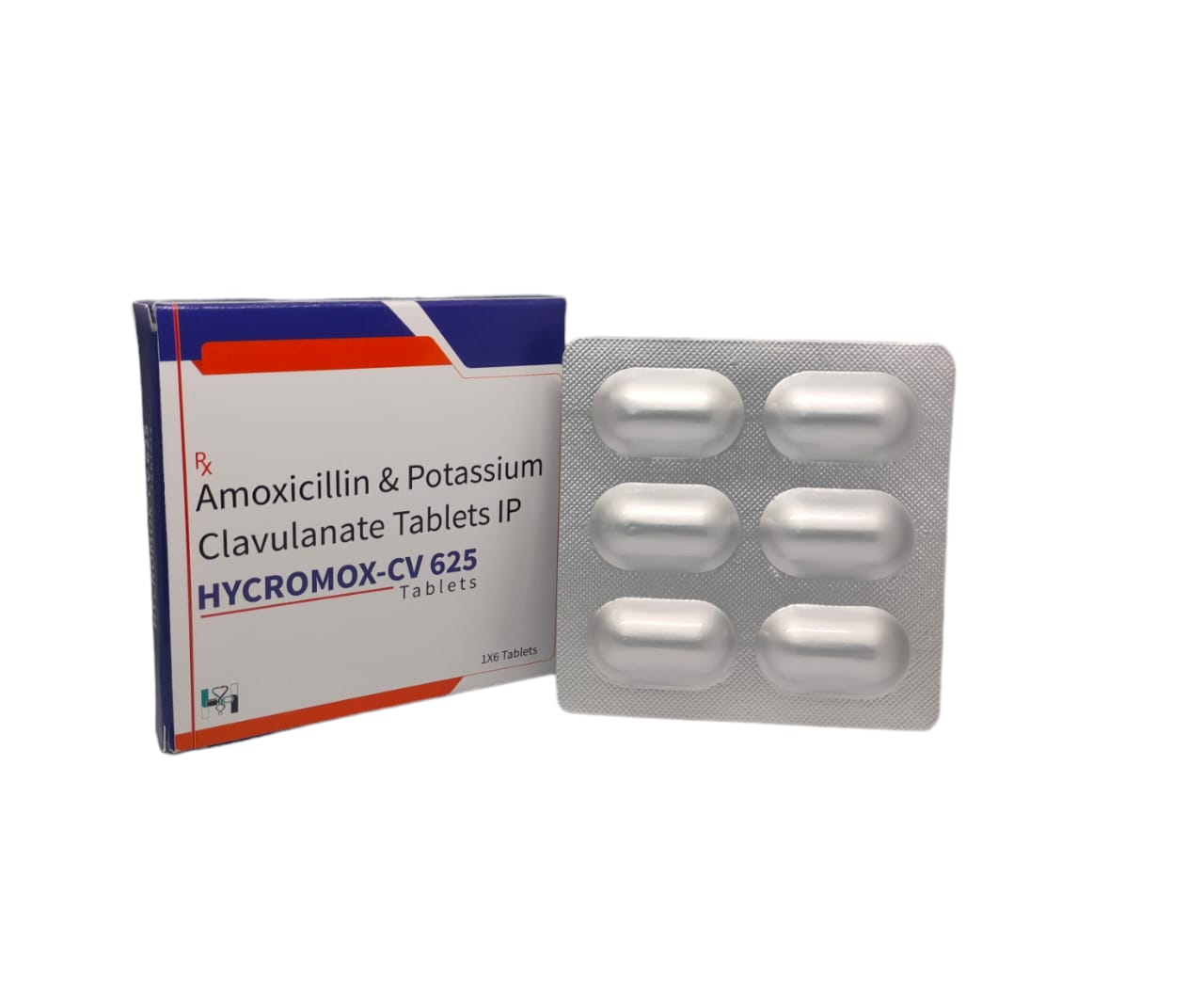

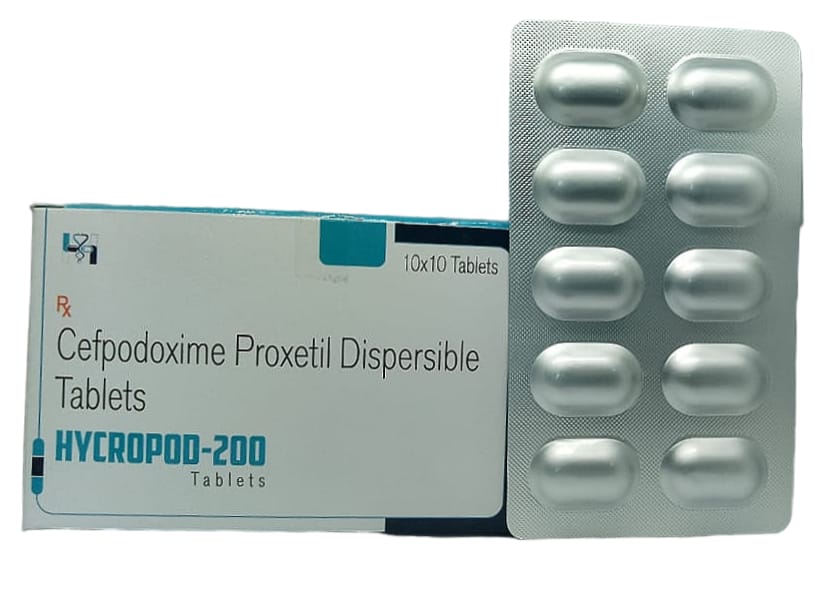

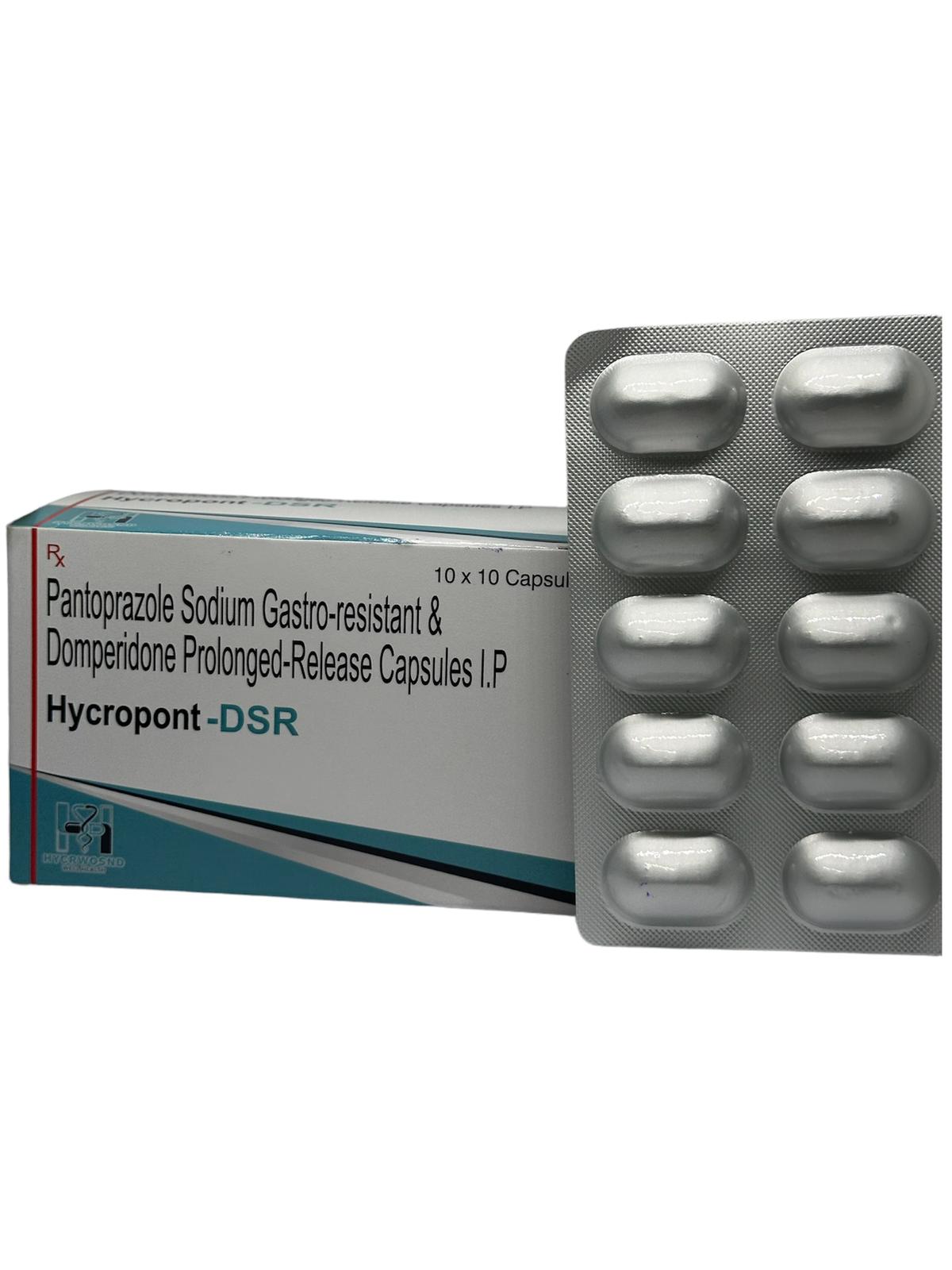

The Start of Our Journey:

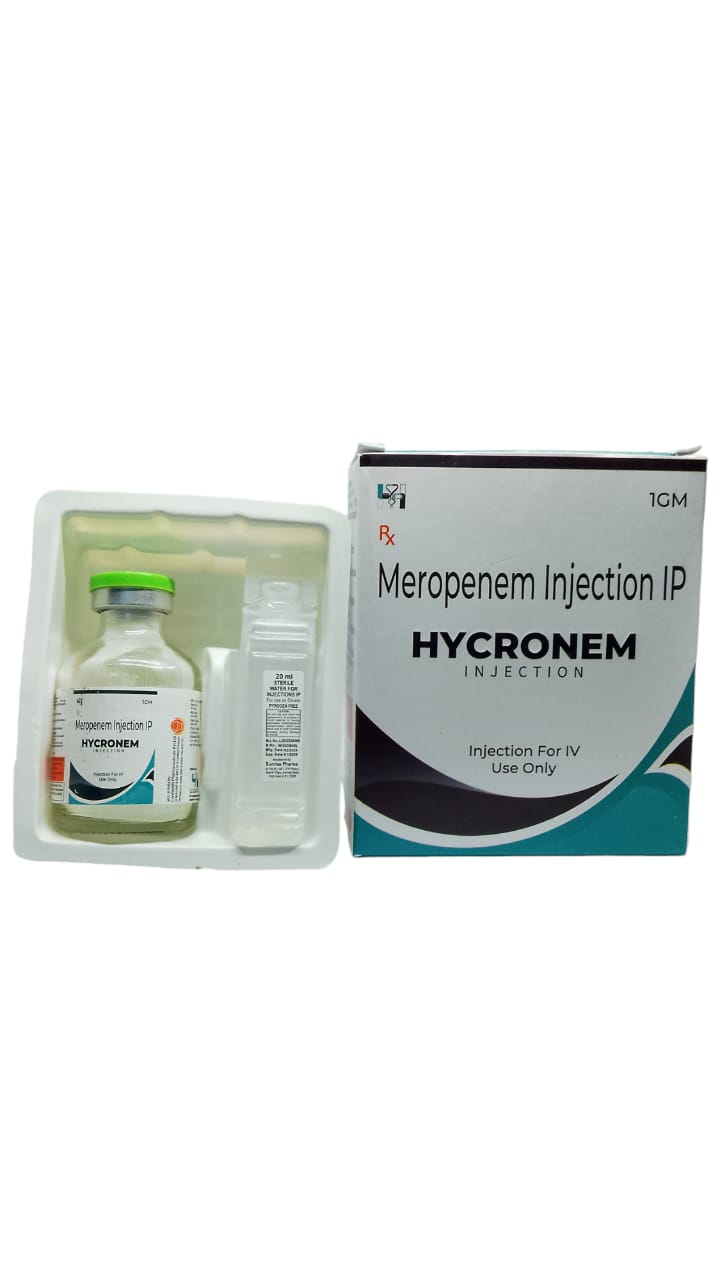

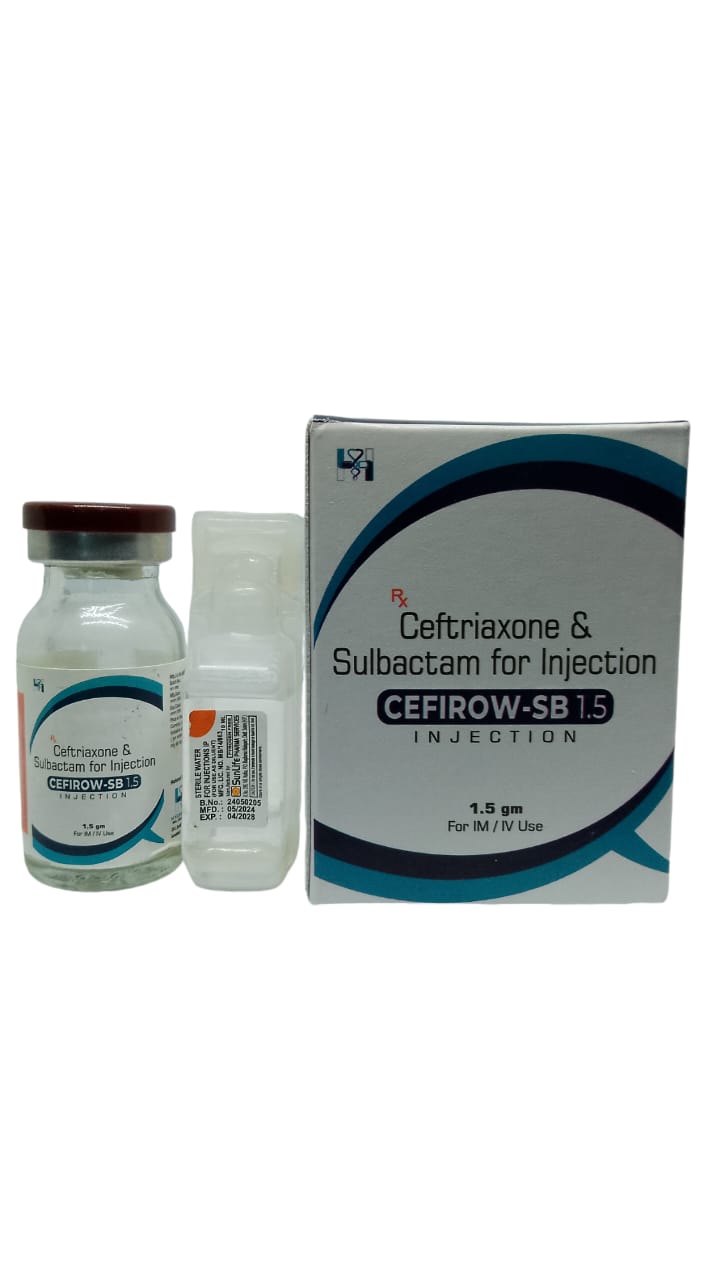

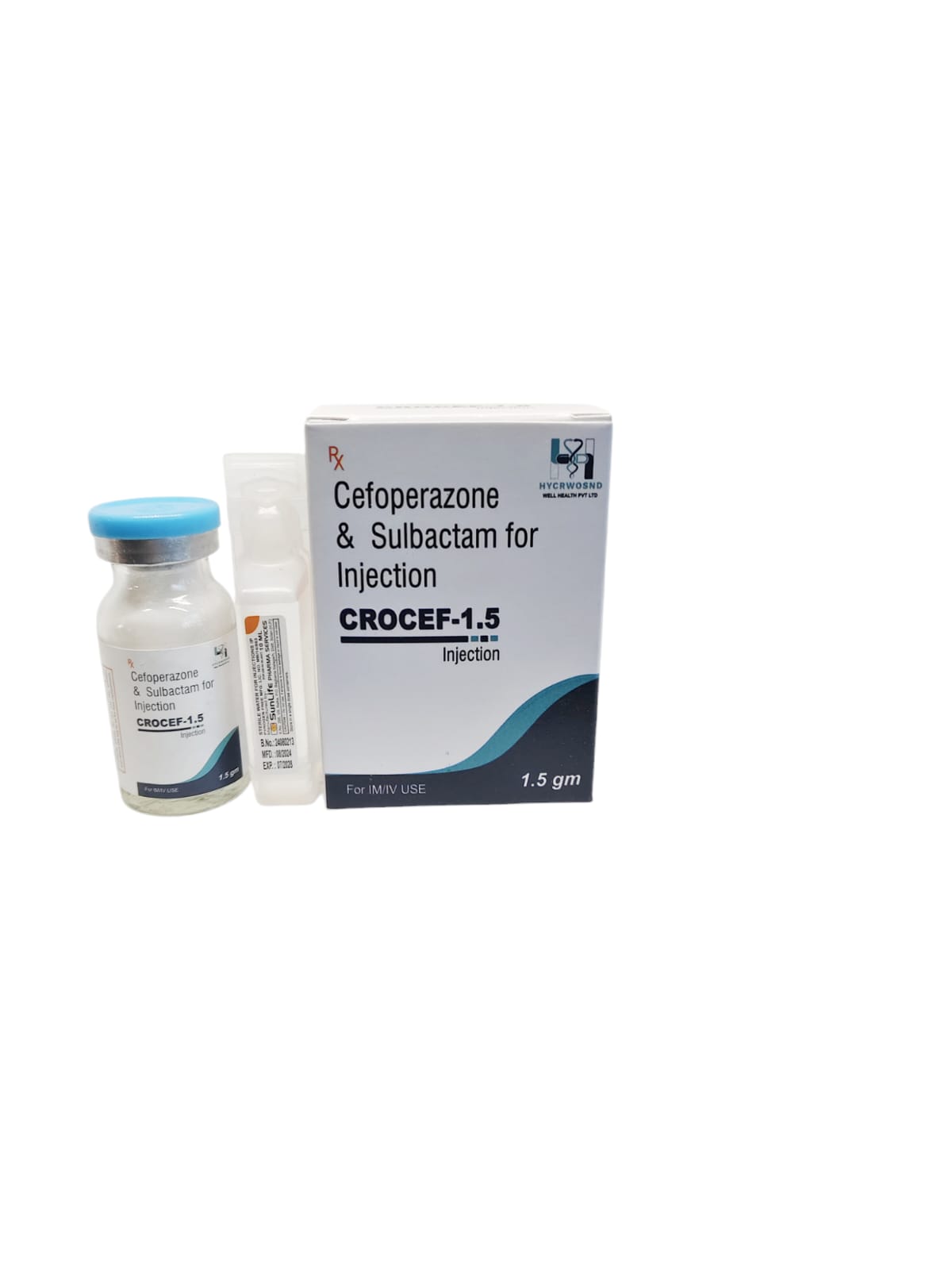

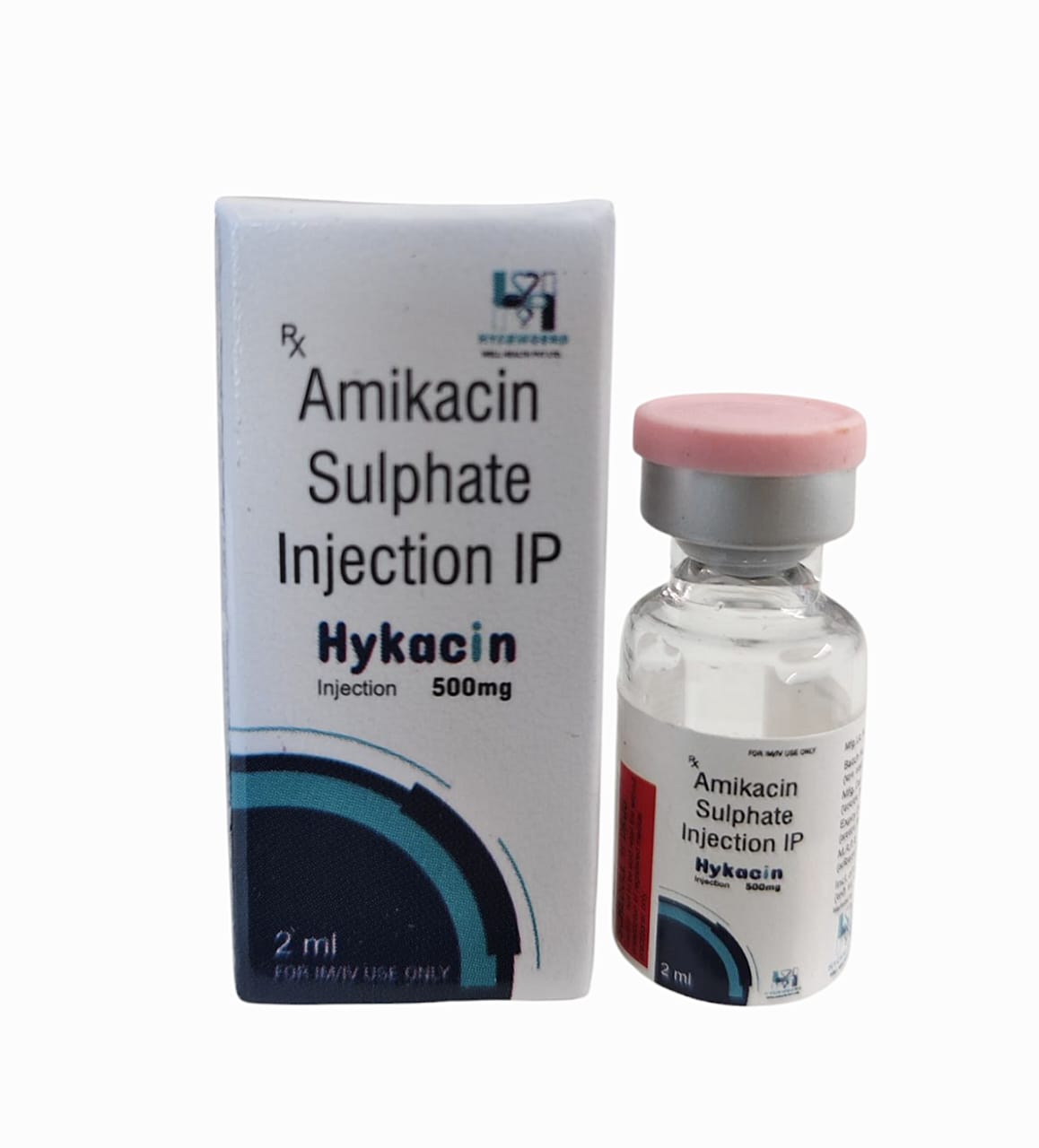

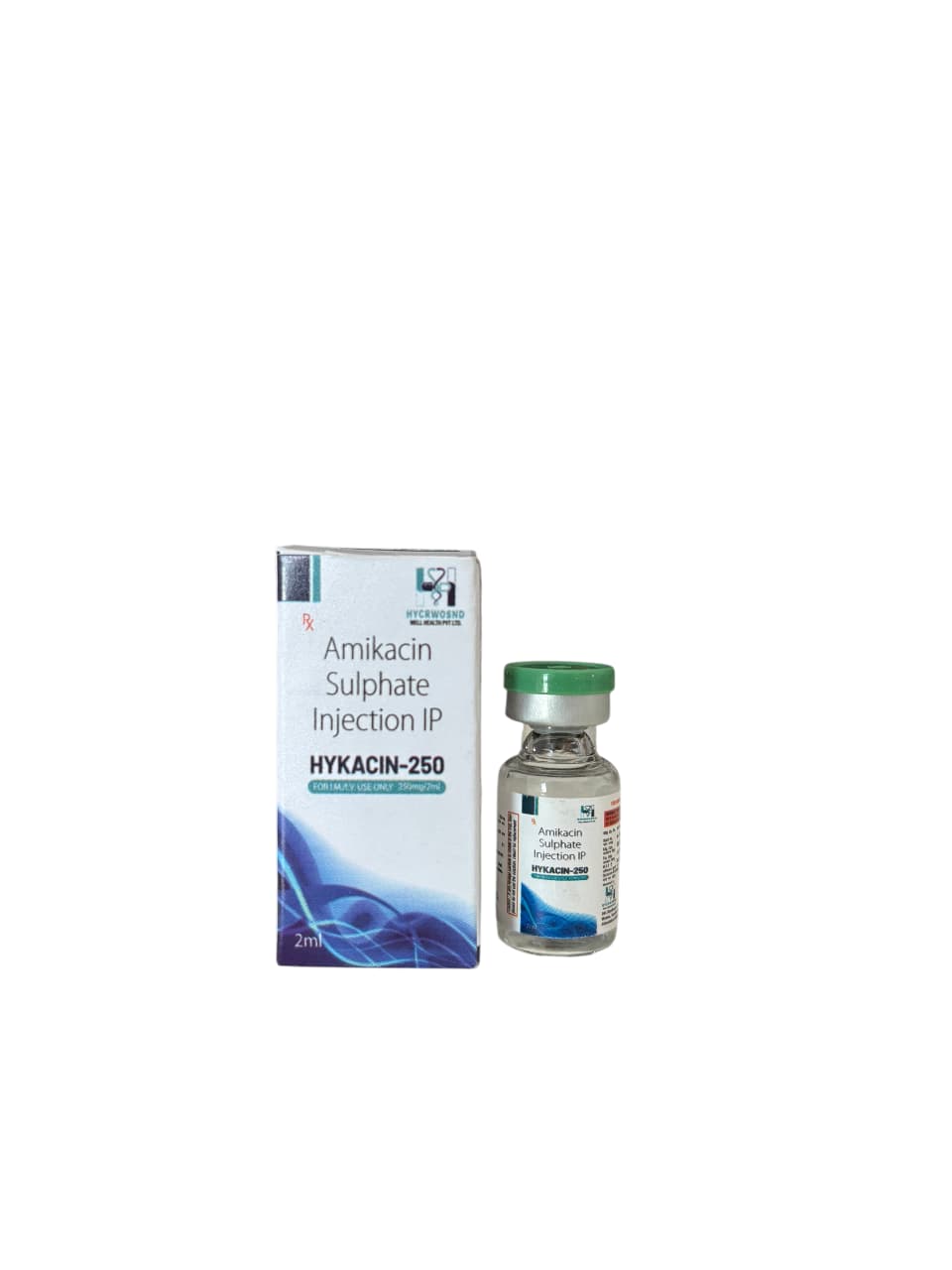

In [2023], the journey of HYCRWOSND WELL HEALTH PVT.LTD began with a singular mission—to redefine healthcare through innovation, quality, and unwavering commitment to patient well-being.

The Start of Our Journey:

In [2023], the journey of HYCRWOSND WELL HEALTH PVT.LTD began with a singular mission—to redefine healthcare through innovation, quality, and unwavering commitment to patient well-being.